- Industry Solutions

- Technology & Products

- Service & Support

- News

- About Us

- Qualification & Honor

- Contact Us

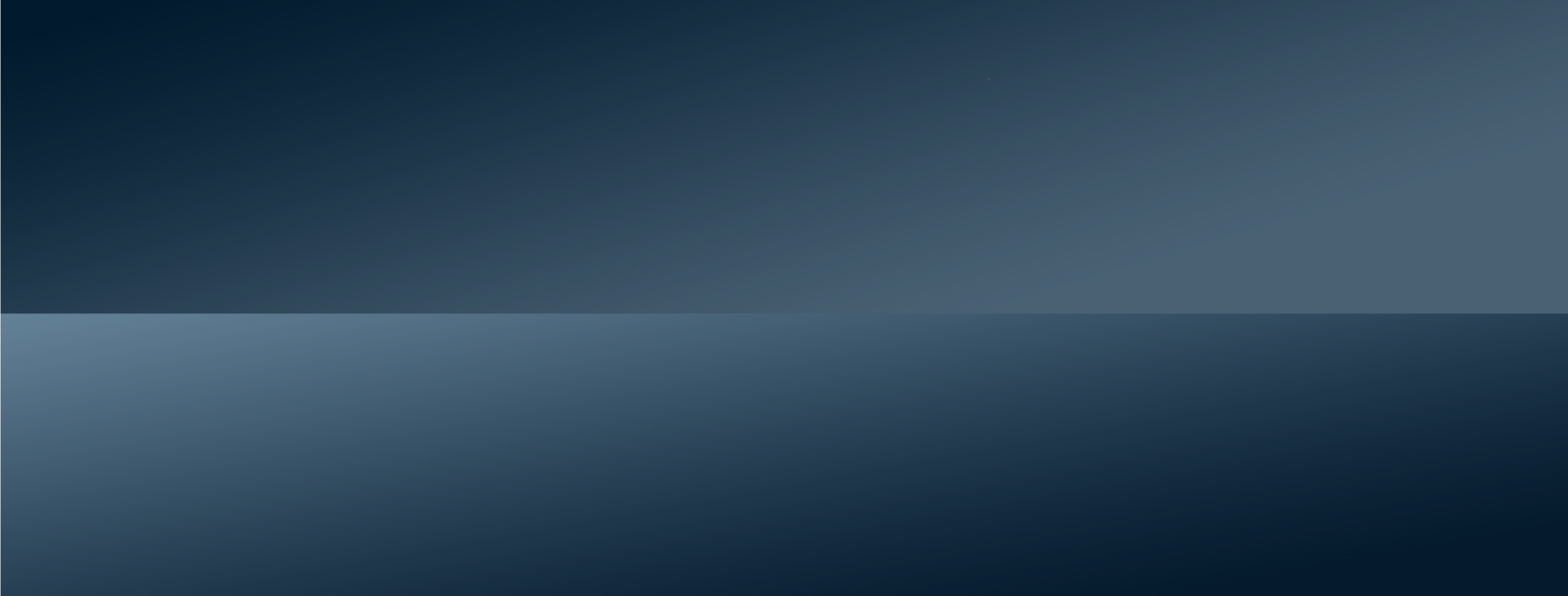

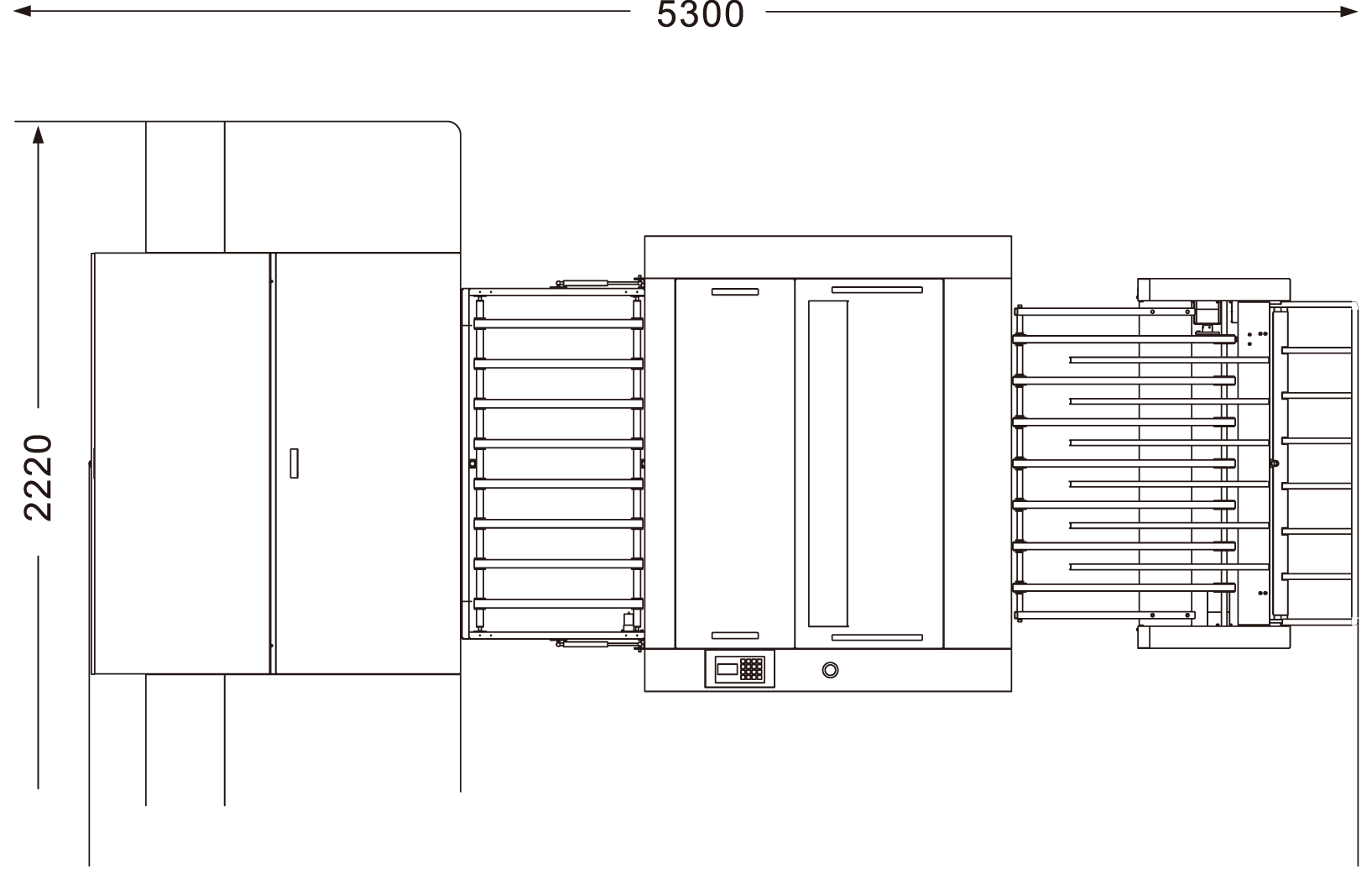

Digital printing starts with our new 2.0CTP, with perfect structure, high-precision image and high-power efficiency. GIS has set up many training centers nationwide to help customers plan production processes and match flexible equipment solutions, and provide prepress training such as the use of equipment and software and color management. The software system is a powerful 1-bit tiff output controller software, which can be connected with a variety of digital workflow standards, professional color, monochrome, multi-color preview, convenient prepress screen inspection, convenient to use the output record query function

Digital printing CTP2.0 perfect structure

High-precision image,

High-power efficiency

| Specification/model | CTP800-II |

|---|---|

| Production capacity | Flat in and out, can be installed continuously |

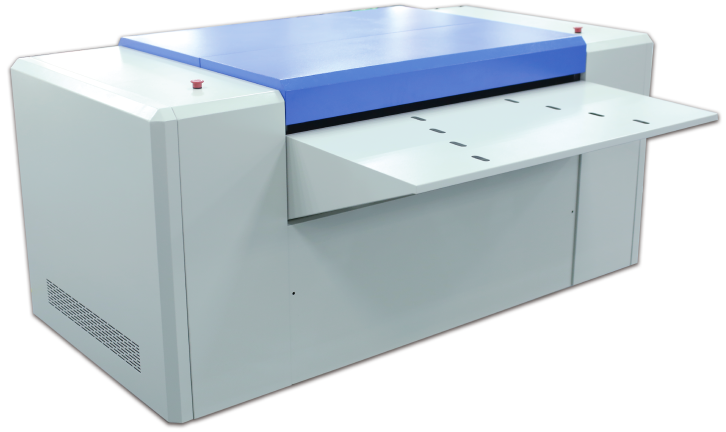

| (including loading time) | Drum |

| Edition preparation | 48 UV lasers 64 UV lasers 96 UV lasers |

| Exposure light source | Max Size 1160x940mm, Mini Size 460x395mm |

| Plate Size | Thermosensitivity(infrared 830nm sensitive) printing plate |

| Plate Type | 0.15-0.4mm |

| Thickness of plate | 2540dpi(optional 2400dpi) |

| Output Resolution | 300Lpi |

| Max number of lines added | 20μm |

| Minimum FM dot output | ±0.005 |

| Repeated precision | 23p/h(1030x800) 28p/h(1030x800) 38p/h(1030x800) |

| Up and down version | Speed matching device(either Heidelberg series or Komori series printing |

| Automatic perforation device | press hang plate positioning hole) |

| Find Edge | Mechanical/optics |

| Automatic loading system | Optional device(800) |

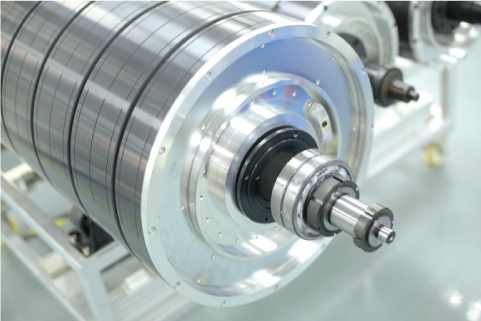

| Separate dust removal unit | The independent optical dedusting unit ensures that the laser and lens are clean |

| Temperature control system Use environment |

and the exposure quality is stable and reliable. Hydraulic temperature control |

| Weight | 23℃+2℃ / 40%-70%humidity |

| Power | 1000KG |

*Specifications subject to change without notice

Jiangsu GIS Laser Technologies Inc.