- Industry Solutions

- Technology & Products

- Service & Support

- News

- About Us

- Qualification & Honor

- Contact Us

On the first day of FESPA exhibition in Munich, Germany, Disheng intelligence ushered in a good start

On May 14, 2019, FESPA Global Printing Expo, which has attracted much attention, was grandly opened in Munich, Germany. Professional printing professionals from all over the world gathered here, which is a feast for the world's top printing technology and top products. The exhibition brings together top star enterprises in the printing industry, representing the highest standards in the international printing industry.

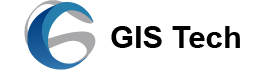

Grand occasion of the exhibition

On the first day of the exhibition, professional friends from all over the world visited Disheng intelligent booth, which was very lively. CTS200 exhibited by Disheng intelligence represents the industry-leading technology of direct plate making of screen laser and is highly recognized by professionals.

Laser CTS direct plate making is a plate making process that uses 405 nm laser module and DMD digital imaging technology to directly carry out high-precision exposure on the surface of the screen. Laser Direct plate making technology is an updated digital exposure system. Laser direct plate making saves film process, saves cost and is more efficient. Laser Direct plate making brings brand-new solutions to the silk print industry. The process of laser direct plate making is simpler and more efficient, and is fully compatible with the traditional silk print plate making process.

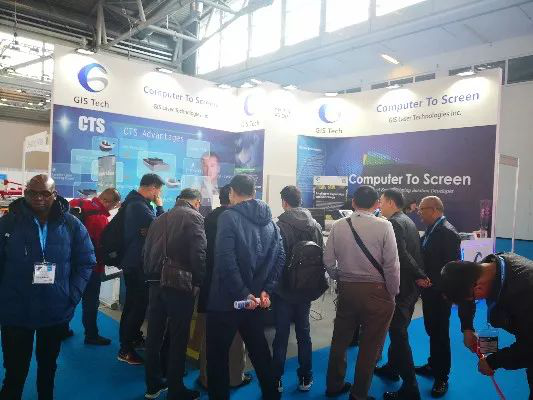

China silk print printing industry association CSPIA German delegation visited GIS booth for exchange and guidance

Wonderful continue! Welcome to Disheng Smart booth! Disheng team is dedicated to serving you and providing you with advanced intelligent manufacturing solutions. With more than 30 years of industrial experience in the industry, we will help you break through the technological bottleneck and plan your future needs together.

Advantages of CTS:

Precision advantage: Resolution 1270dpi/2540dpi, 133 lines added

High capacity: It takes only 3 minutes to expose a 1 square meter network Board

Cost reduction: because there is no need for film, thus preventing film abrasion and unstable expansion and contraction

Quality problems occur, and the film price is relatively high, saving a lot of costs.

Reduce plate making process: reduce the three steps of the traditional work exposure process to CTS

Perform one step of the process to achieve the purpose of fast plate making.

Improve efficiency: accurate exposure alignment, save printing preparation time, and reduce labor at the same time

Application Industry: Printing, label, flower paper, packaging, glass

·CTS ·CTP ·PCB

· Flexible Surface Display Solutions

· Lithium battery automation solution

· Micro-electromechanical Systems, MEMS

· Semiconductor Packaging